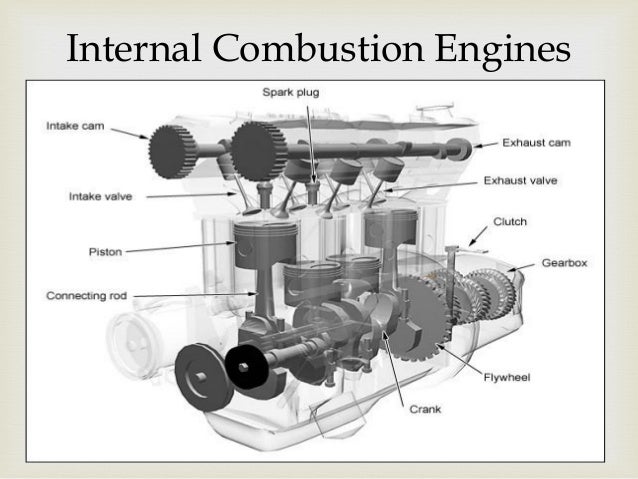

An internal combustion engine (ICE) is a heat engine where the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the

working fluid flow circuit. In an internal combustion engine the expansion of

the high-temperature and high-pressure gases produced by combustion applies

direct force to some component of the engine. The

force is applied typically to pistons, turbine

blades, rotor or a nozzle.

This force moves the component over a distance, transforming chemical

energy into useful mechanical

energy.

The first

commercially successful internal combustion engine was created by Étienne

Lenoir around 1859 and the first modern

internal combustion engine was created in 1876 by Nikolaus Otto (see Otto engine).

The term internal combustion engine usually refers to an engine in which

combustion is intermittent, such as the more familiar four-stroke and two-stroke piston engines, along with variants,

such as the six-stroke piston engine and the Wankel rotary

engine. A second class of internal combustion engines use continuous

combustion: gas turbines, jet engines and most rocket

engines, each of which are internal combustion engines on the same

principle as previously described. Firearms are

also a form of internal combustion engine.

Internal

combustion engines are quite different from external combustion engines, such as steam or Stirling

engines, in which the energy is delivered to a working fluid not

consisting of, mixed with, or contaminated by combustion products. Working

fluids can be air, hot water, pressurized water or even liquid sodium, heated in a boiler.

ICEs are usually powered by energy-dense fuels such as gasoline or diesel,

liquids derived from fossil fuels.

While there are many stationary applications, most ICEs are used in mobile

applications and are the dominant power supply for vehicles such as cars, aircraft, and boats.

Typically

an ICE is fed with fossil fuels like natural gas or petroleum products such as gasoline, diesel fuel or fuel oil.

There is a growing usage of renewable

fuels like biodiesel for compression ignition engines and bioethanol or methanol for spark ignition engines. Hydrogen is sometimes used, and can be made

from either fossil fuels or renewable energy.